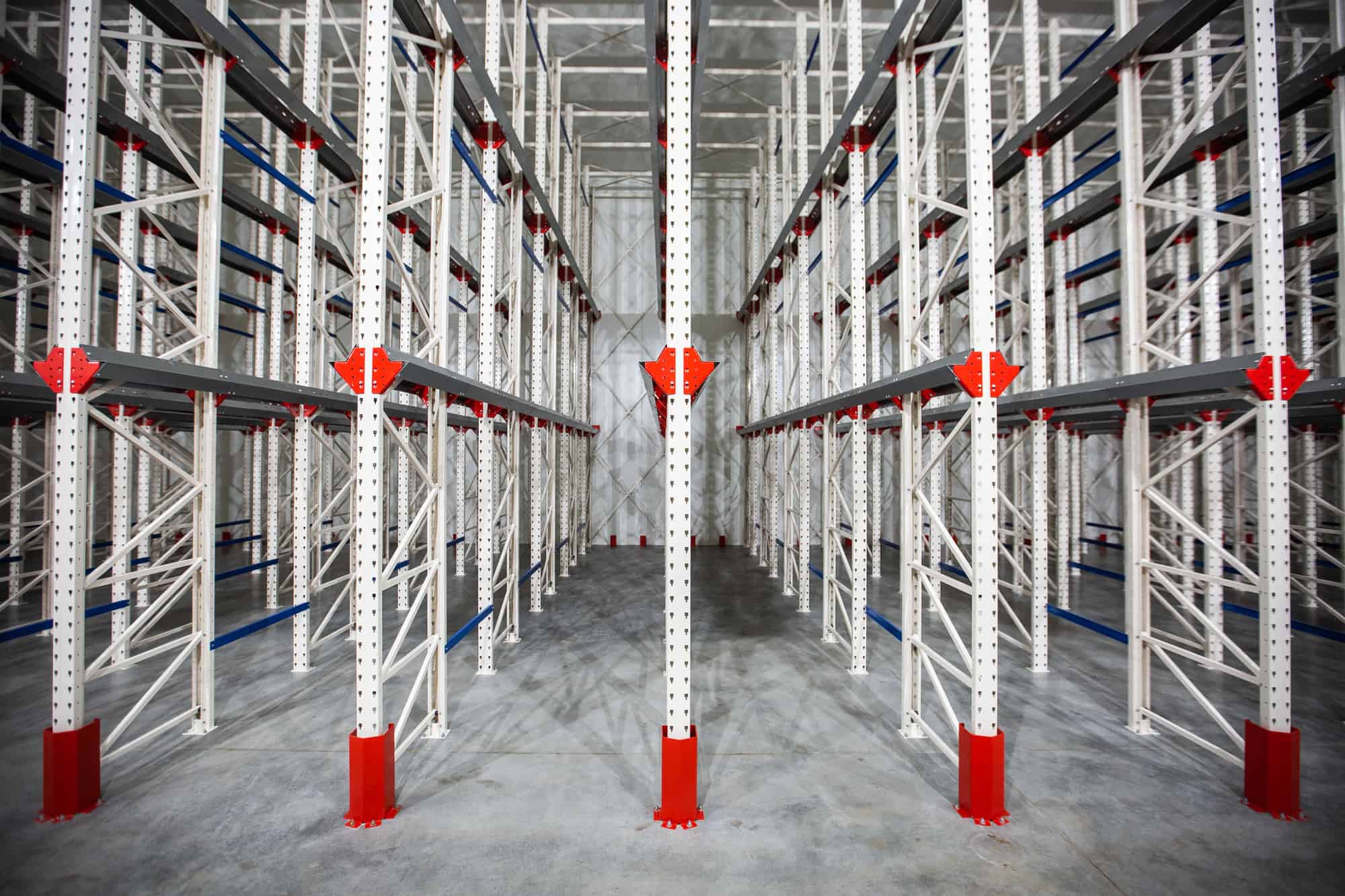

Drive in pallet racking is suitable to store large amounts of the same or similar goods. It is also very well suited for frozen storage or any other storage where the cost of per square meter is high. This is because drive-in pallet racking does not need aisles, therefore making the maximum usage of warehouse space.

Drive-in pallet rack is a high-density rack system that can be designed according to space to maximize storage capacity. Forklifts can drive into the system to load pallets that do not need aisles. This means that you can store more pallets in a drive-in pallet racking system than a selective pallet racking system of the same size.

Drive-in pallet racking allows you to utilize every space in your warehouse since drive-in pallet racking requires front access to only one side of the system and can be used to maximize the storage capacity of a previously unusable space.

As only a few pallets can be accessed from the front of the system, the remaining pallets are stored behind them. This can protect pallets from potential damage caused by forklift collisions.

Drive-in pallet racking can be designed and customized to suit any space or warehousing operations. Drive in pallet racking not only provides high density storage with a single access point, but it can also be designed to have back-to-back entry points where you can access the racking from both sides.

When choosing a drive-in pallet racking system, consider whether your warehouse is designed to provide maximum storage or to increase efficiency. Focusing on the objective you will have better utilization of space or efficient operation. If you want to offer long-term storage to your customers, you need to focus on space utilization.

The size of the warehouse determines the output of products per day. When selecting a drive-in pallet racking system, you should focus on the warehouse layout. You need to pay particular attention to aisles, doors and tunnels to avoid forklifts collision when loading and unloading goods.

The material handling equipment is very important for daily loading and unloading. Considering the lifting truck to be used is especially important. Specific measurements can be taken into consideration when designing a drive-in racking system.

When designing a drive-in pallet racking system, please consider the specific measurements of your warehouse. Pay particular attention to the width and height of the racking that you want to design. As a normal rule, you should add 12 inches on top and at the sides for forklift accessing.

If your budget is limited, you can choose a drive-in pallet racking system as it can offer you efficient use of storage space and allow future expansion.

With forklifts regularly entering in and out the drive-in pallet rack system, it is inevitable that damage will occur. You can deal with this matter by maintenance and protection, specifically the ground rail, steel upright protector and the end-rack barriers.

Don’t hesitate to send us inquiry if you have a project to start or if you want to wholesale racking. We will reply you at earliest – normally within 24H – and give you the best solution.

We do everything we can to help you solve the problem of warehouse storage. Looking forward to be your business partner in near future.

Unit DC10, Room 2201, Building 2, Gate of the Orient Building, No.199 Xinggang Rd., SIP, Suzhou, Jiangsu, China