What Is Cantilever Racking System?

A cantilever racking is a heavy-duty storage device specifically designed to hold large, bulky and oddly shaped materials. Given the fact that items that are not uniform in size or shape can be difficult to store efficiently, so we have cantilever racking system to meet the needs. Cantilever racking provides the perfect storage solution for wood, sheet metal, building materials and household items. Unlike standard racks, the cantilever rack system has no vertical uprights in the front, allowing for easier access and keeping the space unobstructed.

Components of Cantilever Racking

Cantilever racking systems are modular in design and feature multiple structural components. Some of the most important parts of a cantilever racking include:

Cantilever Base

Cantilever bases are essentially anchored to the warehouse floor. They connect the uprights to keep the whole system stable.

Cantilever Column

Cantilever racking posts or columns are connected to the base. They contain holes for attaching the arms and create various levels of storage.

Cantilever Arm

Choosing the right cantilever is critical to creating a stable and safe system. The arm directly supports the warehouse inventory, so the capacity of the arm must be sufficient to carry the weight of the goods.

Cantilever Bracing

Cantilever racking system uses X-shaped, diagonal and horizontal bracing supports. They are attached to the columns to provide lateral stability.

Types of Cantilever Racking

Cantilever racks come in different styles, including roll-formed and structural steel varieties. To ensure long-term durability and stability, steel is often the most reliable material, especially when moving heavy loads that require forklift access. To maximize warehouse safety, high-quality cantilever racks should be able to withstand light contact with machinery.

1. Structural Frame

Structural cantilevers are fabricated using hot rolled structural steel. This type of rack is very durable and has a wide range of load capacities. Since it is made of heavy-duty steel construction, it has excellent strength. It requires little maintenance and can withstand harsh warehouse conditions.

2. Rolled Racks

Rolled cantilever racks are made of cold rolled formed steel. They are made of lighter steel than the structural variety and are sometimes referred to as light-duty cantilever racks. The main advantage of lightweight cantilever racks is their adjust ability. Unlike structural steel cantilevered racks, rolled racks are assembled using boltless pin connectors, allowing for quick and easy installation and reconfiguration when using cantilevered assembly rails. They are often used in high-volume, fast-paced facilities such as food and beverage distribution centers.

Configuration of Cantilever Racking

Depending on the type of products you store and the layout of your facility, you can choose between the single-sided or double-sided cantilever racking.

1. Single-Sided Cantilever Racking

Single-sided cantilever racking is designed with arms on only one side. Rather than having the same arm on the other side, this system is balanced by a strong base which is bolted to the ground. Racks of this type can be placed back-to-back to allow for both sides.

2. Double-Sided Cantilever Racking

Double-sided cantilever racking is designed with arms at two sides. It provides higher storage density than the single-sided. They can be stacked vertically, allowing you to maximize storage space. By adding vertical storage, you can create more floor space.

3. Dixed Single-Sided and Double-Sided Cantilever Racking System

The most common configuration of cantilever racking is a mixed system by both single-sided and double-sided. Single-sided racks are accessible from only one side and are usually assembled against the wall. Double-sided racks provide access for direct pickup from two aisles and are usually settled in middle area back-to-back.

Application of Cantilever Racking in Warehouse

Cantilever racking systems are ideal for long-shaped goods.

Pipe and Wood

Due to its shape and size, storing wood or pipes on traditional pallet racking would be awkward. Cantilever racking systems provide a solution for properly storing such long and thin items. Depending on the actual size of your pipe and lumber inventory, you can choose cantilever racks in different sizes and load capacities.

Building Materials

Building materials such as trim panels, fences, molds, they are difficult items to store. If you just pile them on the ground, you run the risk of seeing them fall and your operator may be injured. We were fortunate to see a cantilever racking solution that not only saves the footprint of your storage space, but also keeps your cargo safely on the arm. The load capacity of your cantilever racking system can be built to help you achieve it in the most efficient and cost-effective manner.

Styling and Decoration Materials

House moldings are also mostly long and irregular, and they may not be as heavy as some of the metals that require heavy duty cantilever racks to store, while medium-duty cantilever racks can be a good option for storing this type of goods.

Steel Bars

Bars of almost any size can be easily stored on the cantilever racking, which is stable enough to provide adequate load capacity. Operators can easily pick up bars from the cantilever racking by hand or a forklift. Ideal to store goods such as steel bars, since this racking system is easy to access and manage.

Metal Sheet

Metal sheet is usually long, wide and thin, making it inconvenient to carry and manage. If you’re still looking for a storage solution for your bulky metal sheet, you should definitely check out cantilever racking. The arms for storing cargo are customized, and the arms can be long enough for your sheet metal to sit comfortably on them.

Furniture

If you are a furniture supplier then you must have a big SKU for your different types of furniture. For those long, large, and heavy loads, it’s important to find a way to make the most use of warehouse space while keeping the furniture sitting well and safely.

Carpet

Carpet rolls or rubber rolls can be quite bulky. Instead of stacking them on the ground, you can stack carpet rolls on cantilevers, which helps save your warehouse floor space.

Advantages of Cantilever Racking

Cantilever racks are a practical solution for your warehouse setup to increase your storage capacity. While they are primarily designed to accommodate a wide variety of large, bulky and long materials, they offer added benefits that help your warehouse run more efficiently.

Adapt to High Capacity Requirements

One of the most important benefits of cantilever racking is its wide range of load capacity. If you need a storage solution to store non-pallet heavy items like aluminum sheets, your options are limited. While floor stacking is a relatively low-cost option, but it does not save space. And it can create safety hazards and reduce a facility’s overall storage capacity.

Cantilever racks allow you to improve your warehouse layout by efficiently storing bulky loads and freeing up floor space. Cantilever racks organize bulky items more efficiently than other systems, enabling seamless product retrieval and warehouse operations.

Since they are configured without shelves, the arms can be easily adjusted using a simple hairpin system. A unique design feature of cantilever racking is their lack of front support columns, allowing forklifts, trolleys and other mechanical picking equipment to access items through the horizontal space between the rack arms. This flexibility and extra space allows you to efficiently store different types of products because you don’t have to rely solely on pallet racks.

Increase Vertical Storage Capacity

Cantilever racking storage systems allow you to use vertical space in your warehouse, offering multiple levels of storage. This creates more floor space, but it also helps improve efficiency with the right spacing. You can optimize space by placing infrequently-used SKU on higher storage units. Since the cantilever racks are easy to use, you can easily retrieve these goods using material handling equipment such as forklifts.

Adjustable and Customized

Cantilever racks are available in a range of customized designs with adjustable shelf heights, different arm lengths and a range of materials to suit your warehouse space. Hairpin retainers allow warehouse operators to quickly adjust arm height if new or different sized goods will be stored. The system can be configured to increase product visibility or improve the loading and retrieval process. Storing heavy or bulky cargo could be a safety hazard. With adjustable sturdy uprights, tilting arms and open storage, the cantilever racking can be accessed safely and easily with a forklift.

Safety Measures When Using Cantilever Racking

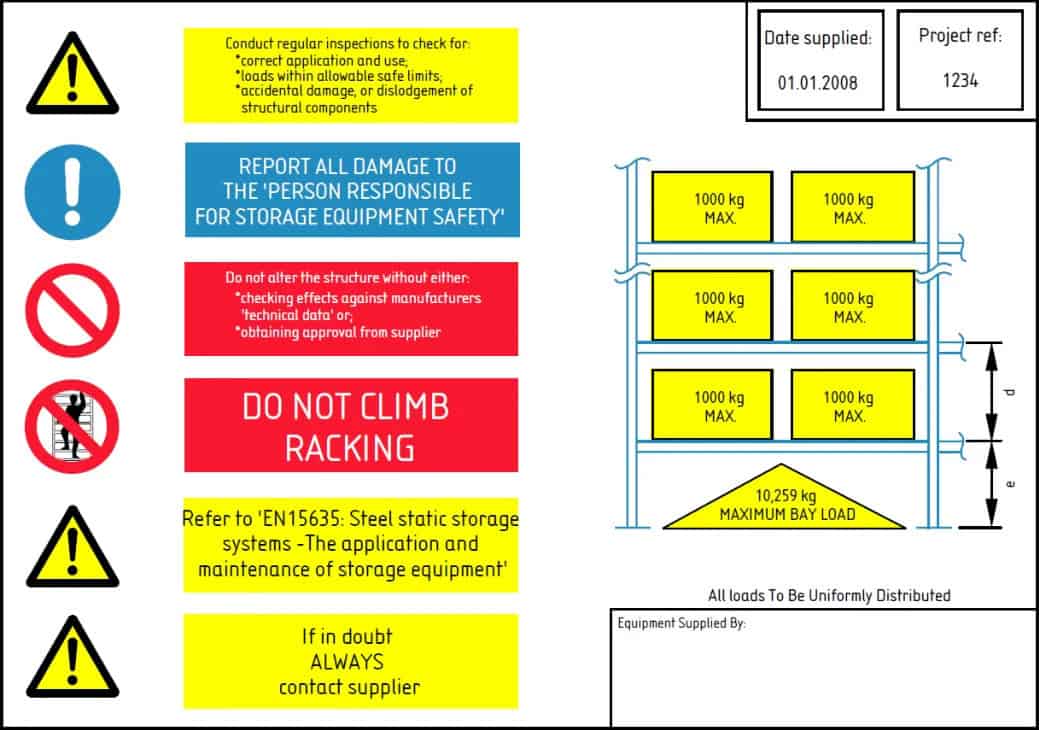

Periodic Inspection

To keep your cantilever racking system working long-term, inspection work is inevitable. If you have a security officer in your warehouse, his day job should include: checking the overall condition of the racking system, checking for misplaced items, and checking that all items are properly stored. In addition to this, the safety officer is also responsible for checking for damaged racks. Once any of that found, make sure to replace them as soon as possible. Due to the daily working hours are limited, safety worker may not have enough time to check each component one by one, then random selection of inspections is very necessary and helpful.

Clearly Marking Load Capacity On Racks

You can have different load capacities for specific rows among the entire cantilever racking system, but you have to be very clear about how much capacity a particular row of racks can hold. This is very serious because any small mistake can lead to painful and irreversible losses. Since the load capacity of a single column or arm can vary, at the beginning you will need to know it and label it very clearly at obvious positions.

Increase Aisle Width

Unlike pallet racking systems, cantilever racking systems require wider aisles for forklifts operation. Given that the goods stored on the cantilever racks are generally long and thin, if the aisle is too narrow, it may increase the chance of the driver brushing the arms. So if your warehouse storage space is limited, be sure to allow more space between aisles, which is a great benefit for forklift drivers.

Be Gentle When Loading and Unloading

Your cantilever is bolted, not welded, which means the connection isn’t always stable. Sometimes for some unknown operation, the bolted area may come to loose. So you are obliged to educate your forklift driver that it is very important to handle with care and to put the weight of the goods evenly on the rack. Even if the whole rack is designed enough capacity, if you distribute too much weight on a single arm, the single arm will over bear its weight. That is not good for the maintenance of the rack. When unloading, be gentle and avoid hitting the bottom of the arm which could cause the connector to pop out.